One of the common issues on site involves the design of development length in the reinforcing bars that we are using. For some engineers development length in bars is generally taken for granted. Nevertheless, it is important to stress out the use of it since this is part of the strengthening of rebar. Development length is the length of embedded reinforcement or a splicing that required developing the design strength of reinforcement at critical section. During site construction, we encountered the limitation in length of the reinforcing bars that we are using. To achieve the full continuity or the 100% continuity, we make sure that the lapping or the lap slice between the two reinforcing bars is sufficient enough and adopted according to design code and standards.

In this article, we will study the development length of reinforcement in tension and the development of standard hooks in tension based on ACI 318-14 code. What does it say about it?

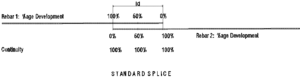

Reinforcing Bars and Its Percentage of Developments:

Development of Reinforcement (R25.4)

The development length concept is based on the attainable average bond stress over the length of embedment of reinforcement (ACI Committee 408 1966). Development lengths are required because of the tendency of highly stressed bars to split relatively thin sections of restraining concrete. A single bar embedded in a mass of concrete should not require as great a development length, although a row of bars, even in mass concrete can create a weakened plane with longitudinal splitting along the plane of bars.

In application, the development length concept requires minimum lengths or extensions of reinforcement beyond all points of peak stress in the reinforcement. Such peak stresses generally occur at the points of maximum stress and points where reinforcement is bent or terminated. From a point of peak stress in reinforcement, some length of reinforcement or anchorage is necessary to develop the stress. This development length or anchorage is necessary on both sides if such peak stress points. Often, the reinforcement continues for a considerable distance on one side of a critical stress point so that calculations need involve only the other side, for example, the negative moment reinforcement continuing through a support to the middle of the span.

Development of deformed bars and deformed wires in tension (25.4.2)

Development length () of deformed bars and deformed wires in tension shall be:

where:

fy: specified yield strength of rebar in MPa

fc’: specified concrete compressive strength in MPa

db: diameter of the bar

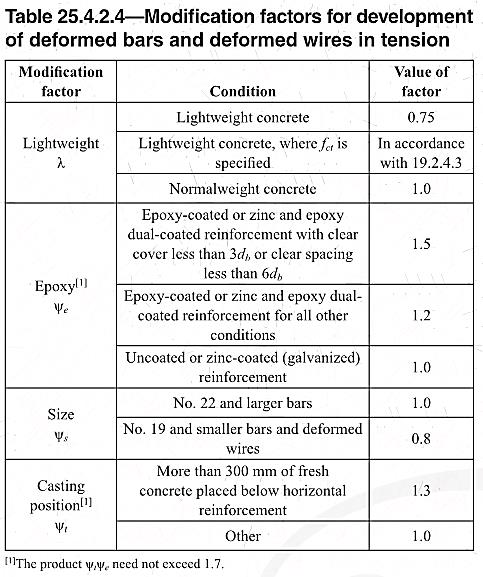

For the modification factors below, refer to table 25.4.2.4 below, an excerpt from ACI 318-14 code:

ψt (psi sub t): development length modification factor for casting location

ψe (psi sub e): development length modification factor

λ (Lamba): modification factor base on reinforcement coating

Development length of standard hooks in tension (R25.4.3)

Study of failures of hooked bars indicates that splitting of the concrete cover in the plane of the hook is the primary cause of failure and that splitting originates at the inside of the hook where local stress concentration is very high. Thus, hook development is a direct function of bar diameter db, which governs the magnitude of compressive stresses on the inside of the hook.

Development length () of a standard hook in tension is greater of 8db, 6 inches and the equation below:

where:

fy: specified yield strength of rebar in MPa

fc’: specified concrete compressive strength in MPa

db: diameter of the bar

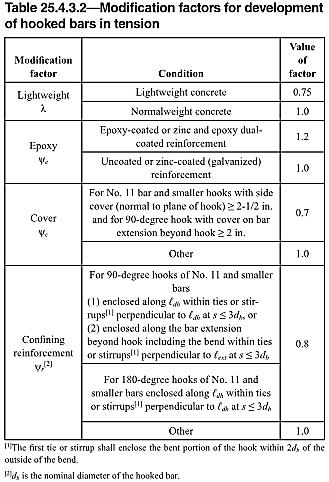

For the modification factors below, refer to table 25.4.3.2 below, an excerpt from ACI 318-14 code:

ψe (psi sub e): development length modification factor

ψc (psi sub c): development length modification factor based on the cover

ψr (psi sub r): development length modification factor based on confining reinforcement

λLambaba): modification factor base on reinforcement coating

Reference: ACI 318-14

What do you think of the above this article? Tell us your thoughts! Leave your message in the comment section below. Feel free to share this article, subscribe to our newsletter and follow us on our social media pages.

![]()

Amazing post thank thanks for sharing it.

Thanks jitendra!

This is good definition for development length

“Development length of standard hooks in tension (R25.4.3)”

It’s amazing that the formula for development length for hooks I found in ACI 318-14 is different than that shown in this article. Am I missing something?

Would like to receive the clearance from the blog writer as if this formula is incorrect, it will result in wrong development of knowledge of readers.

The reference to this article is according to ACI 318-14 itself. I would be glad if you can specify or point out which part is incorrect and your correction is always welcome. Thanks!