A pile cap is one of the types of foundation that consist of a thick concrete pad that is usually supported by piles. This is commonly used in building foundations with the geographical locations having a very low soil bearing capacity. Pile cap serves to transmit the load of the building into the hard strata of the soil via a pile or group of piles. Design-wise, the pile cap design uses a truss system principle that can be designed using a strut and tie method. Designing a pile cap seems to be complicated because a lot of considerations need to take into account to achieve a safe and sound foundation. These considerations include the proper spacing of each pile, the pile cap thickness and so on. To achieve this can only be done by understanding its design principles and proper detailing of pile caps. The designer’s struggle on pile cap design begins with the consideration of what dimensions or pile cap geometry to assume at first. But knowing the correct pile cap dimensions can be considered as a halfway already in design completion.

In this article, we will be dealing with the standards in determining pile cap geometry and dimensions as well as its design considerations. To make it simple, we will break down our design assumption with the following.

1. Recommended Shape and Its Dimensions

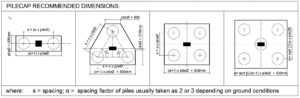

The first thing to consider in the pile cap design is to determine the shape of the pile cap to use. The shapes vary according to the number of piles in the pile cap that can be deriving according to the load in a column supporting it. The figure below shows the most common use shapes of the pile cap and the recommended dimensions.

- Corrections for the above image:

- for 2-Pile Group, length of the pile cap should be (ɑ+1) x Øpile + 300 and

- for the 5-Pile Group, pile to pile spacing would be: s=√(2ɑ) x Øpile

2. Recommended Thickness of Pile Cap

One of the important things to consider in a pile cap design is to determine enough thickness. Pile cap thickness must also be sufficient to meet anchorage-bond length requirements of starter bars and normal punching shear requirements. Here is how to assume the thickness of the pile cap:

- If diameter of pile < 550mm: thickness = 2 x diameter of pile

- If diameter of pile > 550mm: thickness = 1/3[(8 x diameter of pile)-600]

3. Punching Shear Check

Punching shear along the column perimeter should be satisfied according to the standard codes. Also, punching shear due to piles should also be considered in the design check. Further details in punching shear design considerations will soon be published in the succeeding article.

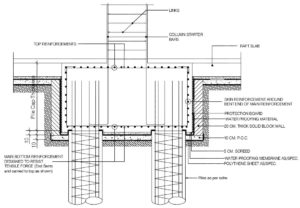

4. Recommended Details

Proper detailing of the pile cap is another thing to consider for design completion. Drawing details should be clear and simple as possible so the contractor can follow it accordingly. Refer to the image below for the recommended typical details of the pile cap.

5. Pile Cap Design Approach

There are so many ways to design a pile cap. Technically, it can be designed manually using a principle of strut and tie method. But if you are considering a wide pile cap supported by multiple numbers of piles, computer-generated structural design soft wares are available to design a massive pile caps.

Otherwise, refer to the Design of PILE CAPS for two, three, and four piles available in excel spreadsheets below. Kindly select the image to avail!

PILE CAP Design Spreadsheets

TWO-PILES | THREE-PILES | FOUR PILES |

|  |  |

The above design assumptions and recommendations are considered as guidelines in considering pile cap as your choice of foundation. Kindly bear in mind that at the end of the day, it is always the structural engineer’s decision and judgment will still follow depending on your guts and prerogative, but at least the above basic knowledge can help you dig in and explore pile cap designing.

Check out the video presentation of the above article that has been presented below. Please be sure to subscribe to our youtube channel as well!

Reference: Reinforced Concrete Designer’s Handbook 10th Edition by Charles E Reynolds and James C. Steedman

Tell us your thoughts, how did you design a pile cap?

Leave your message in the comment section below. Feel free to share this article, subscribe to our newsletter and follow us on our social media pages.

![]()

Copyright secured by Digiprove © 2018-2019 The Structural World

Copyright secured by Digiprove © 2018-2019 The Structural World

What is the source of the recommended thickness of pile cap?

You can refer to pp 421 of Reinforced Concrete Designers Handbook by Charles Reynolds and James Steedman.

KINDLY CAN U SEND ME THE DOUBLE PILING SYSTEM

Two Piles Pile Cap Design is available here https://gumroad.com/l/gYWHe

g+ 4 small residential for group pile and pile cap suggest design

This still depends on the load reactions in each column. You can use a Structural 3D analysis model like ETABS to analyze your building and generate the column loads from there to use for pile and pile cap design.

Piles or type of foundation design depends on the soil-bearing capacity of the project.